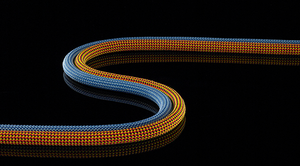

Teufelberger Chalkline - Gym Rope (Maxim - New England Rope)

Teufelberger (New England Ropes)For availability and pricing call 509-291-3024 or email cbknot@cbknot.com

Product Description:

Chalk Line was specifically developed for the punishment gyms inflict on rope. Whether you have a small gym or big wall the Chalk Line can take the constant falls, and belays. The Str8 Jacet Core allows the Chalk Line to hold its shape and keep the cover and core in balance which virtually eliminates sheath Slippage. This will reduce flat spots and help maintain the performance of the over all rope. At 10.8mm or 10.2mm the Chalk Line will provide a safe easy belay through a variety of devices while still maintaining its shape.

Features:

- The Str8 Jacket core Maintains Shape

- Reduces Sheath Slippage

- No Flat Spots

- No More Baggy Rope

Applications:

- Gym Rope

| Size | Falls Held | Weight | Impact Force (kN) | Sheath Slippage (mm) | Static Elongation % | Dynamic Elongation % | Classification | Lengths | Colors | Endura Dry | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| lbs/100' | g/m | ||||||||||

| 10.8 | 8 | 5.2 | 77.4 | 9.7 | 0 | 6.2 | 29 | Single | by-ft, 60M, 200M | Chalkline | STD-DRY |

| 10.2 | 7 | 4.5 | 69.9 | 9.8 | 0 | 6.0 | 26 | Single | by-ft, 60M, 200M | Chalkline | STD-DRY |

Sunlight/UV:

Very little degradation from sunlight. Can be used outside over long term if inspected regularly.

Chemicals:

Nylon will degrade with strong oxidizing agents, mineral acids, and 90% formic acid. May discolor when exposed to high levels of carbon dioxide.

Heat:

Nylon melts at 460°F with progressive strength loss above 300°F.

Dielectrics:

Good resistance to the passage of electrical current. However, dirt, surface contaminants, water entrapment, and the like can significantly affect dielectric properties. Extreme caution should be exercised any time a rope is in the proximity of live circuits.

Sheaves:

N/A

Working Loads:

No blanket safe working load (SWL) recommendations can be made for any line because SWL's must be calculated based on application, conditions of use, and potential danger to personnel among other considerations. It is recommended that the end user establish working loads and safety factors based on best practices established by the end user's industry; by professional judgment and personal experience; and after thorough assessment of all risks. The SWL is a guideline for the use of a rope in good condition for non-critical applications and should be reduced where life, limb, or valuable property is involved, or in cases of exceptional service such as shock loading, sustained loading, severe vibration, etc. The Cordage Institute specifies that the SWL of a rope shall be determined by dividing the Minimum Tensile Strength of the rope by a safety factor. The safety factor ranges from 5 to 12 for non-critical uses and is typically set at 15 for life lines.

Splicing Instructions:

Not Spliceable